Transcript +

Hi, I’m Tom Scarpello of Revology Cars! And this is car number 176, a 1968 Mustang GT 2+2 fastback in Nightmist Blue Metallic with Saddle Nappa leather interior. Today I’m going to take you on a walk around of this car. We’re going to go for a drive. Let’s get started!

All right, ‘68 Mustang GT 2+2 fastback. At the front, fog lamps. The hood is the turn signal hood. It looks very, very similar to the original GT in 1968. At the side, this car is equipped with Torq Thrust wheels, 17×9.5, which allows us to fit a 275ZR/4017 tire. A lot of contact patch, a lot of grip, GT badges. There’s a quarter trim ornament here. The ‘68s were equipped with reflectors in the rear and side markers in the front. That was a federal safety standard in 1968.

At the back, this car is an export unit, so it has the export lighting, which features amber turn signal lenses at the rear. Otherwise, it is straight Mustang GT, just like the original. Look down to the quad exhaust tips. So very, very original. A lot of people will be hard pressed to tell this from an original car.

So this interior is Nappa leather. This is a Mercedes leather Saddle. It’s a popular color. I think it looks great with the Nightmist Blue exterior. The client chose the full leather, so even the headliner, all the rear panels are all leather. The trim is genuine laser cut walnut. Carpet is nylon loop, and it’s a molded carpet. It has a mass backer to reduce noise, vibration, and harshness. Overall, very nice looking interior that looks like it could have been an original 68 Mustang interior.

Okay, so a lot of people ask us why we use the Coyote engine exclusively. So, first, a little bit about the Coyote engine. What is it? It is a version of Ford’s modular engine family. It’s a V8 engine. It features a very sophisticated variable cam timing system. Variable cam timing started to appear in production cars in the early nineties. And what makes it special is it allows the engine to be optimized for operation at different RPM.

So before you had variable cam timing, you had to set the camshaft for a specific operating range. If you wanted an engine that started easily and idled smoothly and had a lot of low end torque to get off the line, you had to optimize the camshaft timing for that, and that meant you sacrificed high end power. If you were building a racing engine or a high performance engine, you wanted the power up higher in the RPM band.

Well, then you had to sacrifice the low end performance drivability. The thing that variable cam timing did was allow the engine to be optimized, you know, in any range. And Ti-VCT – twin independent variable cam timing, is a very sophisticated version of variable cam timing. It allows the intake and exhaust cams to be advanced or retarded independently of each other. So you can truly get the best possible cam timing for a specific RPM range. And that means more power, means better efficiency, but importantly, it means it’s smooth and drivable.

So although you’re making big power at high RPM, you still have a very, very smooth idle. And that is one of the things that really, I think, one of the technologies, and there’s some other ones, that have allowed internal combustion engines to continue to evolve, I think, beyond the expectations of a lot of people.

So, a lot to the Coyote engine. It’s a very sophisticated engine. We don’t really mess with it. We install it as it comes. In fact, the engines come to us on a reusable dunnage. There’s three to a pallet. It’s the same way that they get shipped to the Flat Rock plant where the Mustang is built, and we install it basically the same way that Ford does. Even the calibration is a factory calibration, just with a few things removed that we don’t use. Basic elements of the calibration that make the vehicle run, that make the engine run, we don’t change them at all.

That way, we can preserve the drivability, we can preserve the reliability. Gosh, there’s already plenty of power. It’s like, you don’t need more power. Power is only important relative to the weight that it has to move. And you’ve got a car here that weighs several hundred pounds less than equivalent Mustang GT.

So power to weight ratio is phenomenal. Really more important to have great drivability, great reliability, and, you know, of course, this engine sounds awesome. The only challenge, really, is package, because it is physically a very large engine, and that meant an awful lot of work to get it to fit and operate properly in the 1960s Mustang architecture.

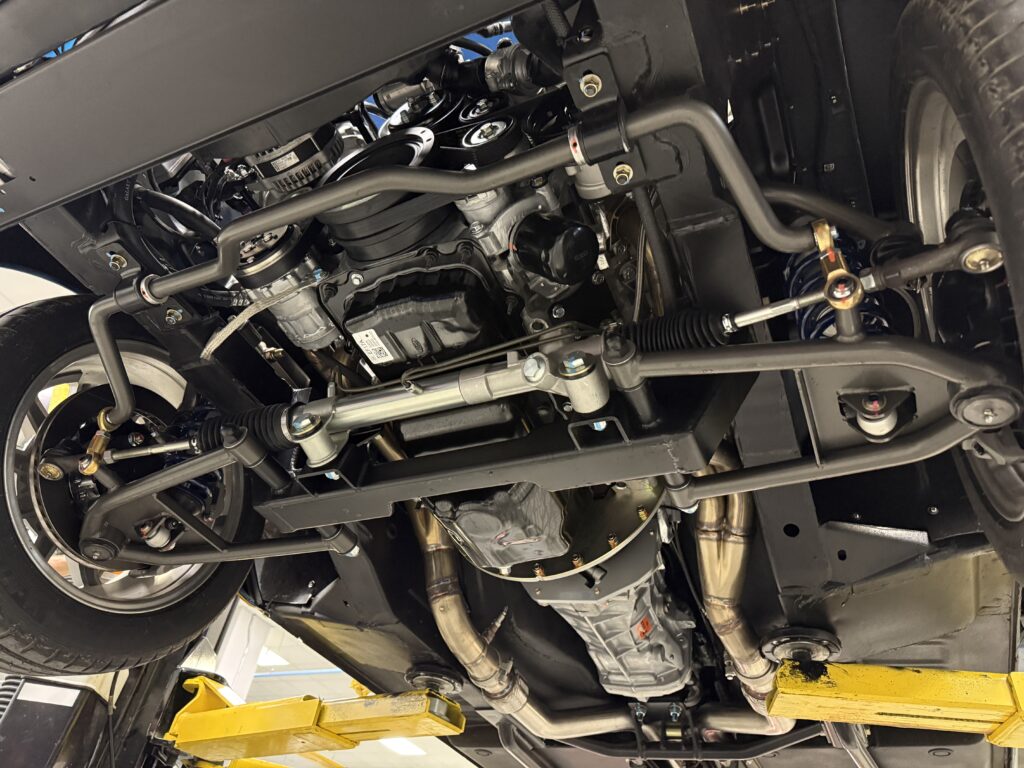

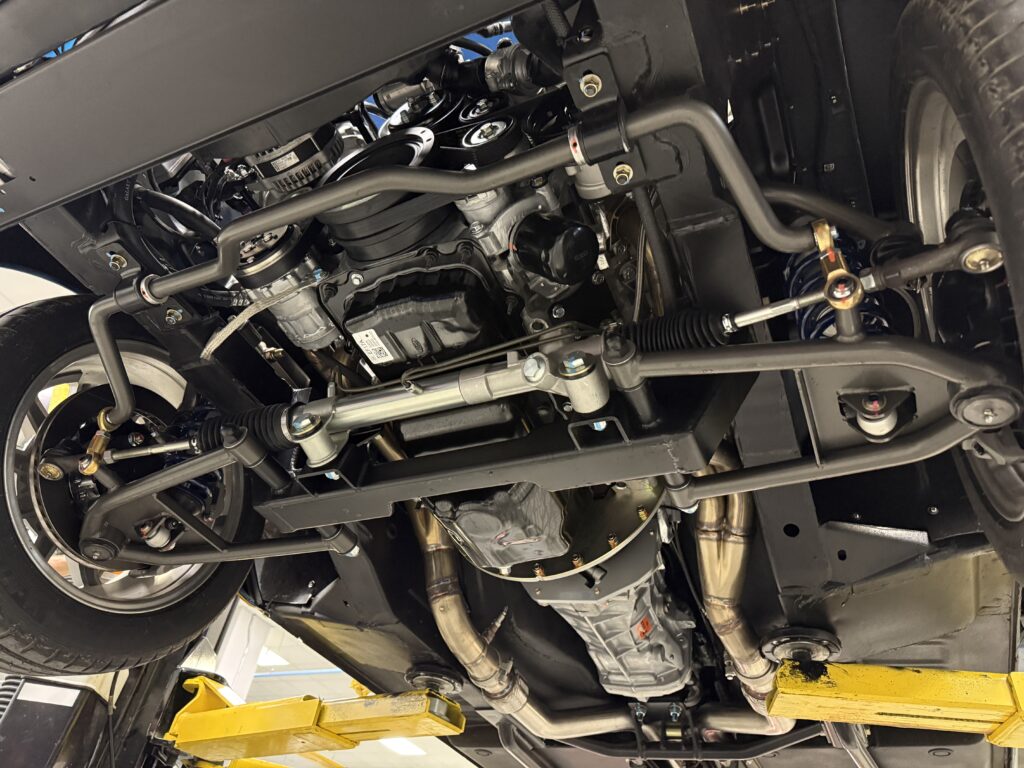

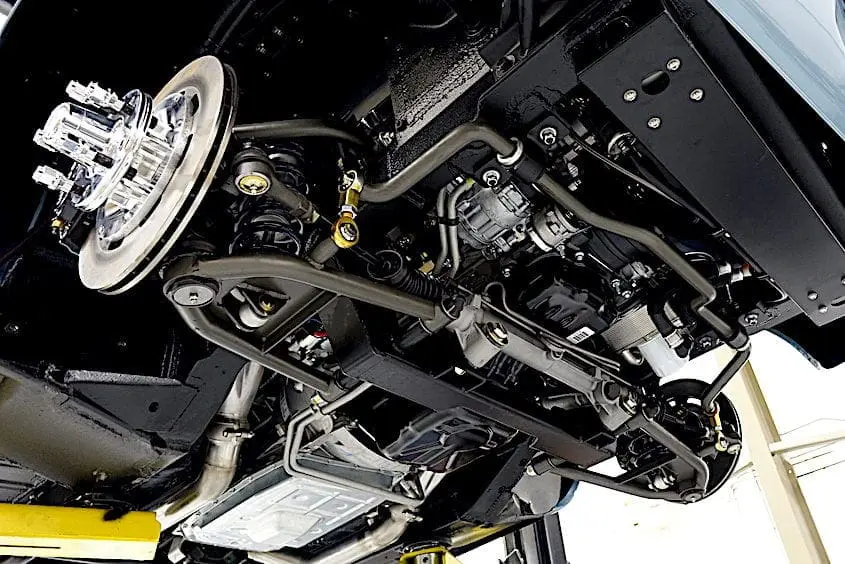

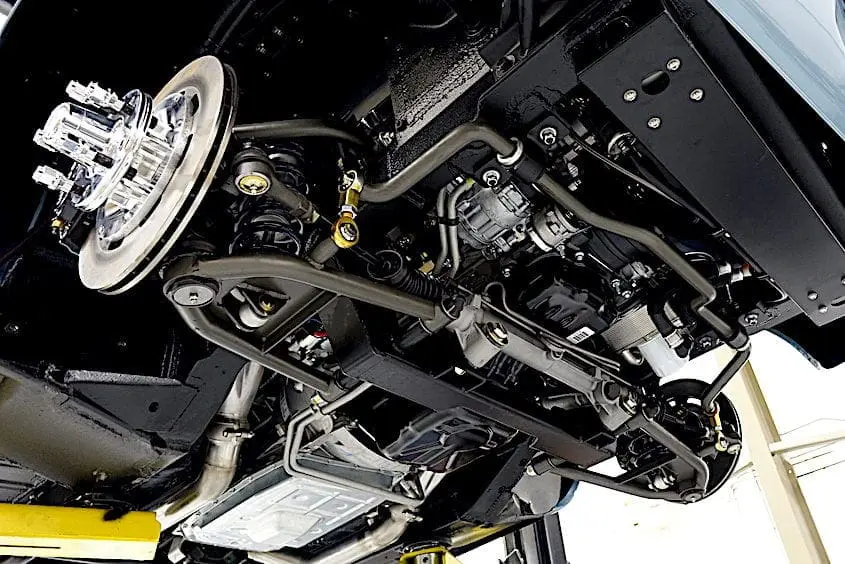

So, a few of those things that I’ll point out is, first of all, brake booster. You can see how tight the package is here where our brake booster and master cylinder are located. We had to move this unit outboard to allow space for the coyote engine. The width of this engine is significantly greater than the original pushrod engine.

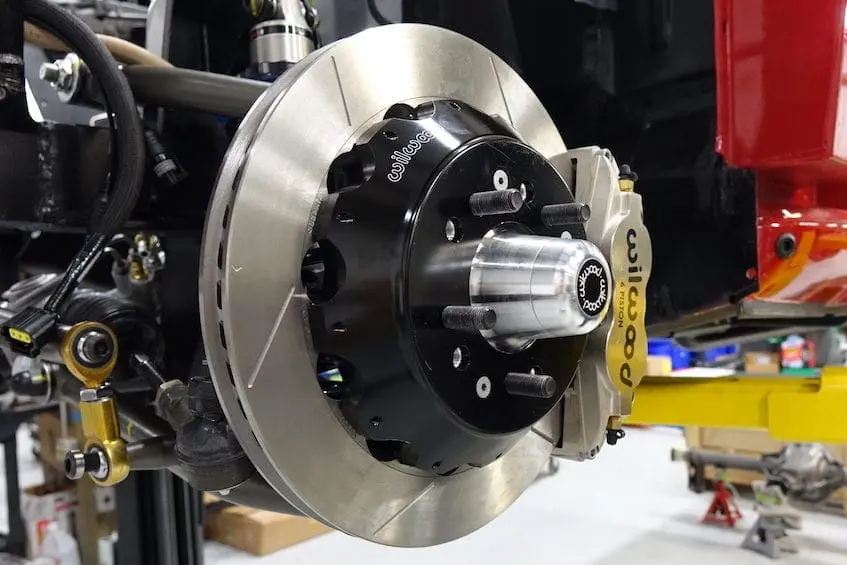

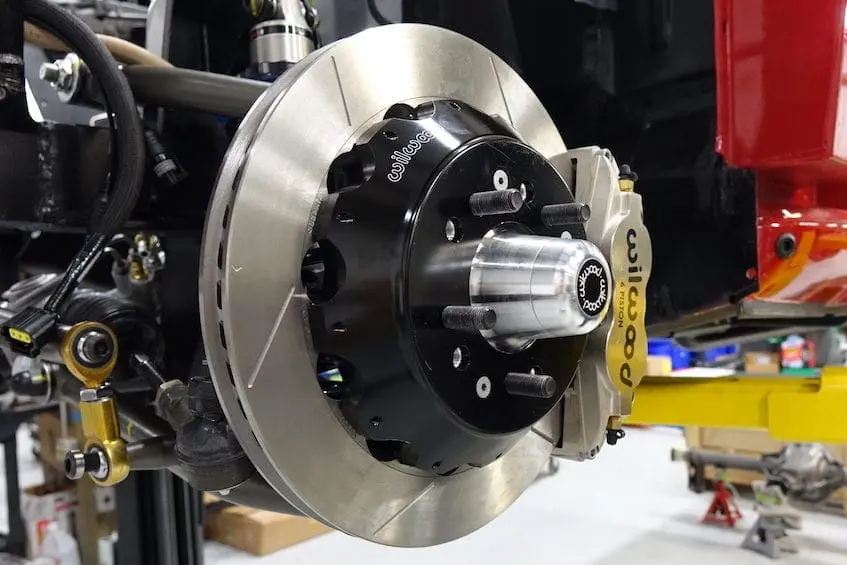

A lot of people that have retrofit a Coyote engine into a 60s automobile found they couldn’t package the booster, and so they end up with giving that up and going with manual brakes. Obviously, we didn’t want to do that. So we went to a hydro boost system, which is smaller. It takes up less space in the engine bay. So combined with moving that assembly outboard and switching from a vacuum booster to a hydro boost, we were able to get power brakes packaged with this engine.

Another thing is the cooling system. And I’ve talked before how we don’t just try to find a radiator and a fan that’ll fit the existing architecture. We actually take the radiator and the fan, the cooling system that we want, and then we change the architecture to package that equipment. We’ve essentially taken the entire Coyote cooling system and built it into our front structure.

So our core support is different. We actually had to move the engine rearward in the chassis to provide enough space to run that much larger cooling system from the coyote engine. So you don’t have any issues with cooling in this package. And we’ve got cars in the hottest places on earth and have never had a cooling problem. It’s definitely critical to maintain the factory cooling package, and then moving the engine back took a lot of work.

But the other benefit there is it improves the weight distribution front to rear. The Mustang historically been kind of a nose heavy car, particularly with the big block versions of the Mustang that had cast iron engine blocks. But this is an aluminum engine, all aluminum. And we’ve moved the engine back in some of our configurations.

We have about a 51/49 weight distribution front to rear. So it’s almost 50/50. It’s really great for handling balance, and then there’s some other things. You know, the Gen3 Coyote specifically has a very sophisticated mass airflow system. So mass airflow MAF or MAF. So the mass airflow sensor measures the amount of air coming into the engine, and then it sends that information to the engine management computer, which then sends the correct amount of fuel to the engine. And it’s really critical that that mass airflow sensor get good information. And this MAF, the Gen3 MAF, is extremely sensitive.

And in our testing, we determined that we needed to completely enclose the air box to reduce any turbulence, because the MAF was picking up just the tiniest bit of turbulence that caused the reading to be a little bit off, and that caused the fuel that was sent to the engine to be a little bit off. And that just affects drivability a bit. And you don’t get really the full performance capability.

When I say performance, I don’t just mean power. I also mean, the drivability and the smoothness. If you don’t have that system optimized, you’re kind of giving up all of this sophistication that you’re paying for, which really doesn’t make any sense. We developed this enclosed system. It brings air in from outside of the engine bay. So it’s bringing in cool air, and it’s allowing that MAF to work like it’s supposed to, getting exactly the right amount of fuel into the engine.

So it’s really just like an OEM package, and it’s a fantastic package. I don’t think there’s any better solution, or there is no better solution for this car than the current Coyote engine.

So every time we use the word Coyote, we get an email from Ford brand compliance. It’s not a Coyote, it is a 5.0 liter Ti-VCT V8 engine. We don’t have a trademark for the Coyote name, so I get it, I understand. I’m sorry, but everybody calls it a Coyote. I mean, what are you gonna call it? Is that a twin independent variable cam timing engine in there, or is that a Coyote? I think it’s Coyote. Yeah.

So, I talked about why we use the Coyote engines. Great engine. People ask, why. Why don’t we use the Voodoo engine? Voodoo, the 5.2 liter engine that was in the Shelby GT350 flat plane crank engine, which, cool engine. Would love to use it. But that flat plane crank engine produces a lot of vibration, requires special engine mounts, and we don’t have the packet space for it. And we’ve been asked why we don’t use the Godzilla engine. Godzilla is a 7.3 liter truck engine.

Well, that’s a truck engine. Yes, it can be modified to produce more power and maybe sacrifice some torque. But then you’re modifying an engine, and it’s still, it’s a big, heavy engine. It’s a cast iron block. And we would have to completely redesign our engine package. And, you know, as I described in the overview, there’s a tremendous amount of work that went into packaging the Coyote engine, and we couldn’t feasibly have both engines. There’s just too much to do it right. There’s just too much work. You know, there’s a lot of people that say, oh, yeah, we can put a Coyote in it.

Well, okay. I mean, just putting it in there. Sure. But is it going to be optimized? Is it going to work properly? Is it going to have proper cooling? Is it going to have proper fuel delivery? You know, is it going to be packaged right. Can you run power brakes? You know, there’s a lot of questions. It’s not just as simple as checking the box that says it has the Coyote engine. And that’s why it’s all we do.

I mean, we just don’t have the engineering resources to do a different engine for every car because it’s just not possible to do it right. It’s not possible, period. It’s not feasible. It’s not economically feasible. Anything’s possible. It takes time and money, but it’s not economically feasible. And, you know, this is a business, after all, and what we do has to be economically feasible.

Subscribe to our newsletter to learn about our latest news and updates.