Hi, I’m Tom Scarpello of Revology Cars, and this is car number 88, a 1966 Shelby GT350 in Wimbledon White with Guardsman Blue stripes. Today we’re going to take you through the specs and features on this car, as well as introduce a new Revology innovation, polyurethane bonded windshield and backlight glass. So, let’s talk about the specs and features on this ‘66 GT350.

First of all, the front, very similar to the original appearance. Key differences that you’ll see are LED headlamps. The hood, because the Shelby used a fiberglass hood, it came with hood pins to keep the edges down because the hood would tend to flex, and you need that extra additional fastener there. This car is equipped with the locking flush mount latches. Around the passenger side, this car is equipped with the torque thrust wheels. This was not an original Shelby option, but it is period correct aftermarket, so they look great.

Now, this car is equipped with our combined Nappa leather and leatherette material. So the door panels, the seat surfaces, the dash, the most prominent areas of the interior that you would touch, feel. Those are covered in Porsche Nappa leather. And seat backs and the interior panels in the rear, those are covered in a leatherette.

So people often ask me, why don’t we do a reality show? Wouldn’t it be really cool? And I always say, no, because we’re way too boring and nobody would watch it. And to give you an example, I’m about to describe our newest innovation, polyurethane bonded windshield glass, to give you an example of how exciting what we do is. No, actually, it is really exciting. I know it sounds like it’s only exciting if you’re an engineer, but the benefits that you get as the owner of the car that has this technology, that’s what’s really exciting.

First, we need to distinguish between sealers and adhesives. So, sealers are designed to keep water and wind out. That’s it. Adhesives are designed to bond two things together. The original Mustang glass had a rubber seal, and it kept water out mostly. But the polyurethane glass not only seals, but it also bonds. So it actually makes the glass a structural part of the body. And this is really significant.

Now, the development of polyurethane bonded glass started in the late 60s and first went into production in the 70s. Couple of the early cars that featured polyurethane bonded glass were the 1973 old Cutlass, 1976 Audi 100. But by the 1980s, all manufacturers were using polyurethane bonded glass. Just because the benefits were so significant.

First of all, it’s about safety. Because that glass is bonded to the body, it’s not going to pop out. It’s another barrier to ejection. And another reason is, now that that glass is part of the body structure, it stiffens up the body, and it reduces the possibility of roof crush in a rollover. So that’s added safety feature.

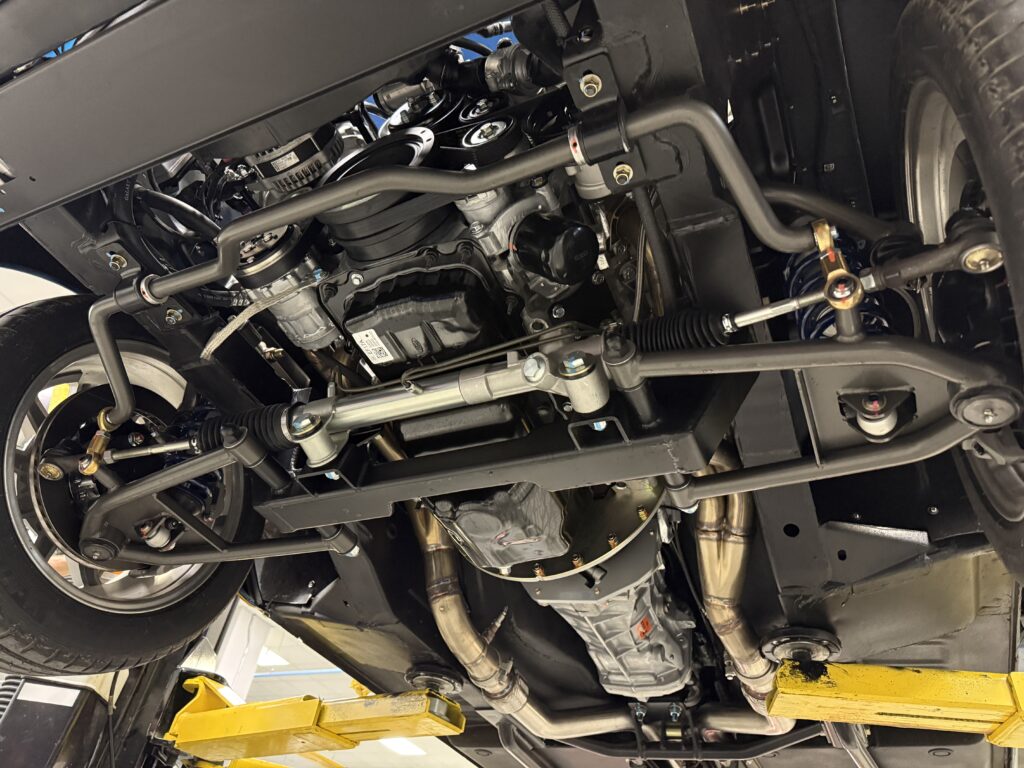

And frankly, that added structure gives more stiffness, more torsional rigidity to the body. Torsional rigidity is something that engineers are constantly striving to improve. I mean, you read about new cars that come out, and the manufacturer brags about, oh, the body is 25% stiffer than the old body. Well, why is that so important? Well, because the stiffer the body structure is, the more that the suspension can work and do its job effectively. That’s really the reason.

And when you consider cars that were designed in the 60s, in terms of their level of torsional rigidity versus a modern car, they were significantly inferior to modern cars. The polyurethane bonded glass is one of the reasons. So, of the many things that we do at Revology to improve torsional rigidity of the body, this is just one more thing, one more incremental step, but it really makes a significant difference, and it’s very well worth it. And this is one more example of why, at Revology, we don’t build them like they used to.

So, back to the polyurethane bonded glass. So, the question is, can you feel it? Can you feel the difference? Well, you know, with all the little incremental changes, it’s sometimes difficult to isolate any particular change. But what I can say is the car feels very solid, very stiff. The other day, we had one of our early cars. Car 7 was back for service.

I could immediately tell the difference. Not that it was bad, it was just a lot more similar to what an early mustang was like. We started to build our own unibodies in house, and we’ve made so many improvements to the unibody to make them more stiff, rigid. And then this is just the latest change. That’s what we do. It’s continuous innovation. That’s our culture, I would say we have a culture of innovation at Revology Cars.