Small volume, big thinking – Revology Cars’ unique approach to specialty car production

Behaving like a big carmaker is the secret to success in the world of small volume specialty cars.

Revology Cars, the highly touted Florida-based maker of reproduction original Ford Mustangs, has adopted this strategy and the results are clear: sophisticated, repeatable, high quality cars and satisfied customers.

“Our clients want a classic car that is reliable, comfortable, and a joy to drive,” says Tom Scarpello, CEO of Revology Cars. “We do it by acting like an OEM.”

Revology Cars’ OEM (Original Equipment Manufacturer) approach gives it a significant edge over its competition. “In our industry we are unique,” says Scarpello. “It’s about having a vehicle that is systems engineered, versus modifying a classic vehicle with a collection of aftermarket parts that may or may not be compatible. This is one of the many things that make Revology special.”

Scarpello explains that because Revology builds every vehicle using the same platform, it is able to optimize that platform around multiple OEM parts and systems, an approach that requires a considerable amount of engineering work yet generates huge benefits in functionality, as well as serviceability.

To achieve this level of functionality and quality requires discipline. The level of vehicle integration in a Revology build is significant, just like in a modern car. A change to one system can affect many other systems. While Revology’s selection of colors and interior trim is virtually limitless, when it comes to vehicle function, the company is very strict regarding deviations. “You can have any engine you want, as long as it is the current Ford 5.0 liter Ti-VCT ‘Coyote’, naturally aspirated or supercharged,” quips Aaron Wright, the company’s chief engineer. “This engine is so deeply integrated into the vehicle architecture that it would require a new engineering program to fit a different engine.”

Some clients, who are not accustomed to being told “no”, are surprised at first by this approach. “We have to turn down a lot of requests because of the high degree of vehicle integration,” says Yoshi Amano, marketing and sales director at Revology Cars. “But once the client understands that there is a sound rationale to our method – regarding quality execution – they get it.”

Specific examples of Revology Cars’ system engineering approach include:

Cooling. Revology uses the same cooling system that was designed by Ford for the Coyote V8 engine. The Ford-sourced radiator and cooling fan system required a significant redesign to the vehicle’s front structure. The result is a cooling system that can handle any operating condition, including track work, without overheating. The Ford-sourced dual fans are whisper-quiet, and the client has the security of knowing that if replacement parts are ever required, they can be easily sourced from any Ford dealer.

OEM drivetrain calibration. Revology only uses new engines and transmissions sourced from Ford, with factory calibrations. The factory calibrations were developed by teams of calibration engineers, who test them in every possible operating mode and atmospheric condition of temperature, altitude, and humidity. The factory calibrations go far beyond the capability of an aftermarket tuner by optimizing performance while maintaining drivability, reliability, emissions, and fuel economy.

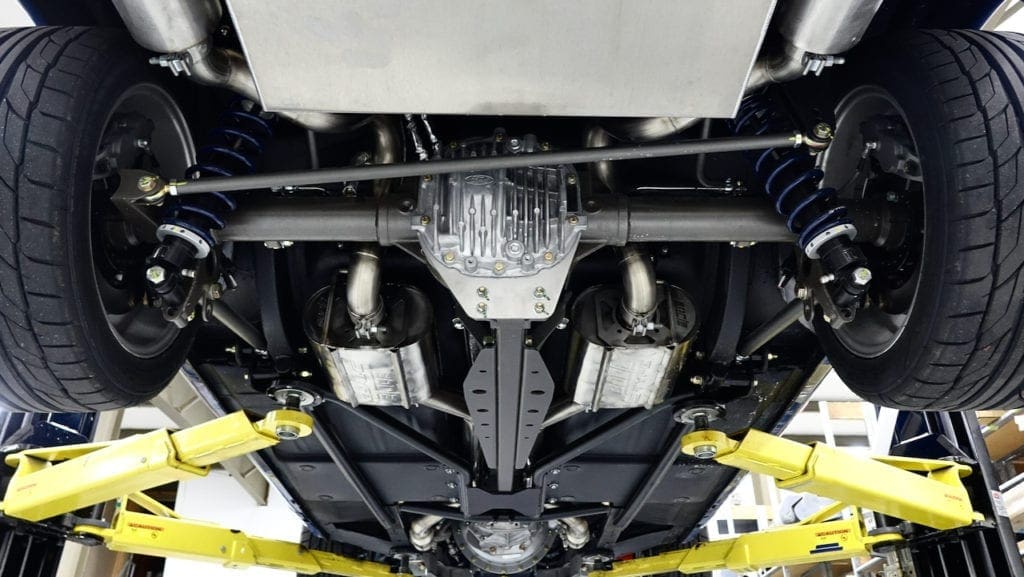

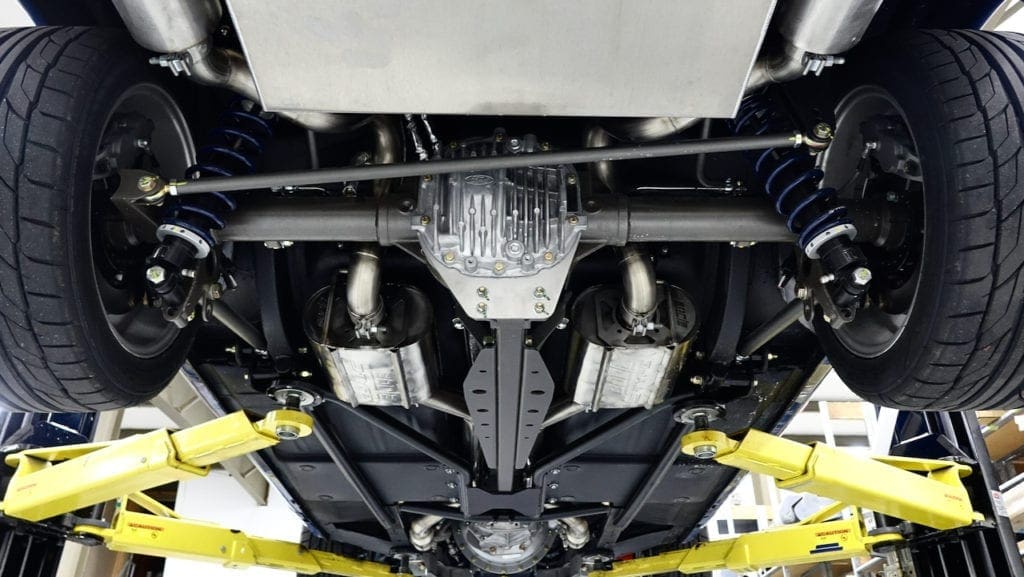

Rear axle assembly. For years, hot rodders have used the Ford nine-inch rear end, because it is durable, inexpensive and easy to service. However, by modern standards, it is noisy. Given that Revology vehicles are often used to drive long distances, the whine from the nine-inch axle was considered unacceptable. To address this, Revology adopted Ford’s current production 8.8 inch gearset, which is not only quiet, but robust enough to handle the output of the supercharged 710-hp plus Coyote engine. As with the radiator modifications, this move required considerable work to modify the rear suspension to accommodate the more modern rear axle assembly.

Wiring harness. While there are multiple companies making harnesses for restoring or upgrading classic cars, Revology knew that none could fully integrate the company’s sophisticated, inter-related electrical requirements, so the company designed its own. But while the harness design is bespoke, it is made with OEM components and produced by a major OEM supplier. The two main body harnesses and modular sub harnesses are used on all Revology models. They are routed and fastened to OEM specifications, and the wires are even color-coded to match the harness of the 2020 Ford Mustang.

“Restomods have grown in popularity, but now people are noticing the limit of the restomod approach,” says Scarpello. “A Revology vehicle is not a restomod; it is a thoughtfully developed, fully integrated automobile. We are going much further than the competition.”

Revology is the first company ever licensed by Ford to build a new reproduction Ford. It is also one of a handful of companies worldwide licensed by Shelby.

Revology offers a complete lineup of licensed reproduction 1965-1968 Mustang and Shelby GTs. Detailed specifications including content and pricing can be found on the Revology Cars website at www.revologycars.com, or by contacting Revology Cars directly at (800) 974-4463 / email at info@revologycars.com